| Facility No | Facility Name | Dimension |

|---|---|---|

| DS-M-01 | Induction Heater No. 01 | 100kW × 50kHz |

| DS-M-02 | Induction Heater No. 02 | 150kW × 8kHz |

| DS-M-03 | Induction Heater No. 03 | 50kW × 100kHz |

| DS-M-04 | Induction Heater No. 04 | 100kW × 50kHz |

| DS-M-05 | Induction Heater No. 05 | 100kW × 100kHz |

| DS-M-06 | Induction Heater No. 06 | 150kW × 35kHz |

| DS-M-07 | Induction Heater No. 07 | 150kW × 100kHz |

| DS-M-08 | Induction Heater No. 08 | 150kW × 50kHz |

| DS-M-09 | Induction Heater No. 09 | 200kW × 30kHz |

| DS-M-10 | Induction Heater No. 10 | 150kW × 15kHz |

| DS-M-11 | Induction Heater No. 11 | 150kW × 30kHz |

| DS-M-12 | Induction Heater No. 12 | 150kW × 30kHz |

| DS-M-13 | Induction Heater No. 13 | 100kW × 120kHz |

| DS-M-14 | Induction Heater No. 14 | 100kW × 120kHz |

| DS-M-15 | Induction Heater No. 15 | 150kW × 8kHz |

| DS-M-16 | Induction Heater No. 16 | 150kW × 8kHz |

| DS-M-20 | Induction Heater No. 20 | 50kW × 200kHz |

| DS-M-21 | Induction Heater No. 21 | 30kW × 120kHz |

| DS-M-22 | Induction Heater No. 22 | 100kW X 120kHz |

| DS-M-23 | Induction Heater No. 23 | 100kW × 100kHz |

| DS-M-24 | Induction Heater No. 24 | 100kW X 50kHz |

| DS-M-25 | Induction Heater No. 25 | 30kW X 120kHz |

| DS-M-26 | Induction Heater No. 26 | 30kW X 120kHz |

| DS-M-27 | Induction Heater No. 27 | 30kW X 120kHz |

| DS-M-28 | Induction Heater No. 28 | 30kW X 120kHz |

| DS-M-29 | Induction Heater No. 29 | 100kW X 120kHz |

| Facility No | Facility Name | Dimension |

|---|---|---|

| DS-M-001 | Induction Heater No. 01 | 100kW × 120kHz |

| DS-M-002 | Induction Heater No. 02 | 100kW × 100kHz |

| DS-M-003 | Induction Heater No. 03 | 100kW × 80kHz |

| DS-M-004 | Induction Heater No. 04 | 100kW × 80kHz |

| DS-M-005 | Induction Heater No. 05 | 100kW × 80kHz |

| DS-M-006 | Induction Heater No. 06 | 100kW × 80kHz |

| DS-M-007 | Induction Heater No. 07 | 100kW × 80kHz |

| DS-M-008 | Induction Heater No. 08 | 100kW × 80kHz |

| DS-M-009 | Induction Heater No. 09 | 150kW × 20kHz |

| DS-M-010 | Induction Heater No. 10 | 100kW × 80kHz |

| DS-M-011 | Induction Heater No. 11 | 100kW × 80kHz |

| DS-M-012 | Induction Heater No. 12 | 150kW × 8kHz |

| DS-M-013 | Induction Heater No. 13 | 150kW × 20kHz |

| DS-M-014 | Induction Heater No. 14 | 50kW × 120kHz |

| DS-M-015 | Induction Heater No. 15 | 100kW × 120kHz |

| DS-M-016 | Induction Heater No. 16 | 150kW × 20kHz |

| DS-M-017 | Induction Heater No. 17 | 150kW × 20kHz |

| DS-M-018 | Induction Heater No. 18 | 150kW × 20kHz |

| DS-M-019 | Induction Heater No. 19 | 150kW × 20kHz |

| DS-M-020 | Induction Heater No. 20 | 100kW × 120kHz |

| DS-M-021 | Induction Heater No. 21 | 100kW × 80kHz |

| DS-M-022 | Induction Heater No. 22 | 100kW × 120kHz |

| DS-M-023 | Induction Heater No. 23 | 150kW × 20kHz |

| DS-M-024 | Induction Heater No. 24 | 100kW × 100kHz |

| DS-M-025 | Induction Heater No. 25 | 50kW × 120kHz |

| DS-M-026 | Induction Heater No. 26 | 30kW × 250kHz |

| DS-M-031 | Induction Heater No. 31 | 150kW × 13kHz |

| DS-M-032 | Induction Heater No. 32 | 30kW × 350kHz |

| DS-M-033 | Induction Heater No. 33 | 30kW × 350kHz |

| DS-M-034 | Induction Heater No. 34 | 30kW × 150kHz |

| DS-M-035 | Induction Heater No. 35 | 150kW × 50kHz |

| DS-M-036 | Induction Heater No. 36 | 100kW × 50kHz |

| DS-M-037 | Induction Heater No. 37 | 100kW × 100kHz |

| DS-M-038 | Induction Heater No. 38 | 150kW × 8kHz |

| DS-M-039 | Induction Heater No. 39 | 100kW × 100kHz |

| DS-M-040 | Induction Heater No. 40 | 100kW × 50kHz |

| DS-M-041 | Induction Heater No. 41 | 150kW × 10kHz |

| DS-M-042 | Induction Heater No. 42 | 100kW × 100kHz |

| DS-M-043 | Induction Heater No. 43 | 100kW × 80kHz |

| DS-M-044 | Induction Heater No. 44 | 100kW × 50kHz |

| DS-M-045 | Induction Heater No. 45 | 100kW × 100kHz |

| Facility No | Facility Name | Dimension |

|---|---|---|

| DS-M-61 | Heating furnace No.1 | w1365×h1775L×L1800 |

| DS-M-62 | Heating furnace No.2 | w1365×h1775L×L1800 |

| DS-M-63 | Heating furnace No.3 | w1365×h1775L×L1800 |

| DS-M-64 | Heating furnace No.4 | w1365×h1775L×L1800 |

| Facility No | Facility Name | Dimension |

|---|---|---|

| DS-M-081 | Heating furnace No.1 | w900×h900L×L1500 |

| DS-M-082 | Heating furnace No.2 | w1000×h1000L×L1800 |

| DS-M-083 | Heating furnace No.3 | w1000×h1000L×L1800 |

| DS-M-084 | Heating furnace No.4 | w900×h1200L×L1800 |

| DS-M-085 | Heating furnace No.5 | w500×h500L×L1000 |

| DS-M-086 | Heating furnace No.6 | w1000×h1000L×L1800 |

| DS-M-087 | Heating furnace No.7 | w1000×h1000L×L1800 |

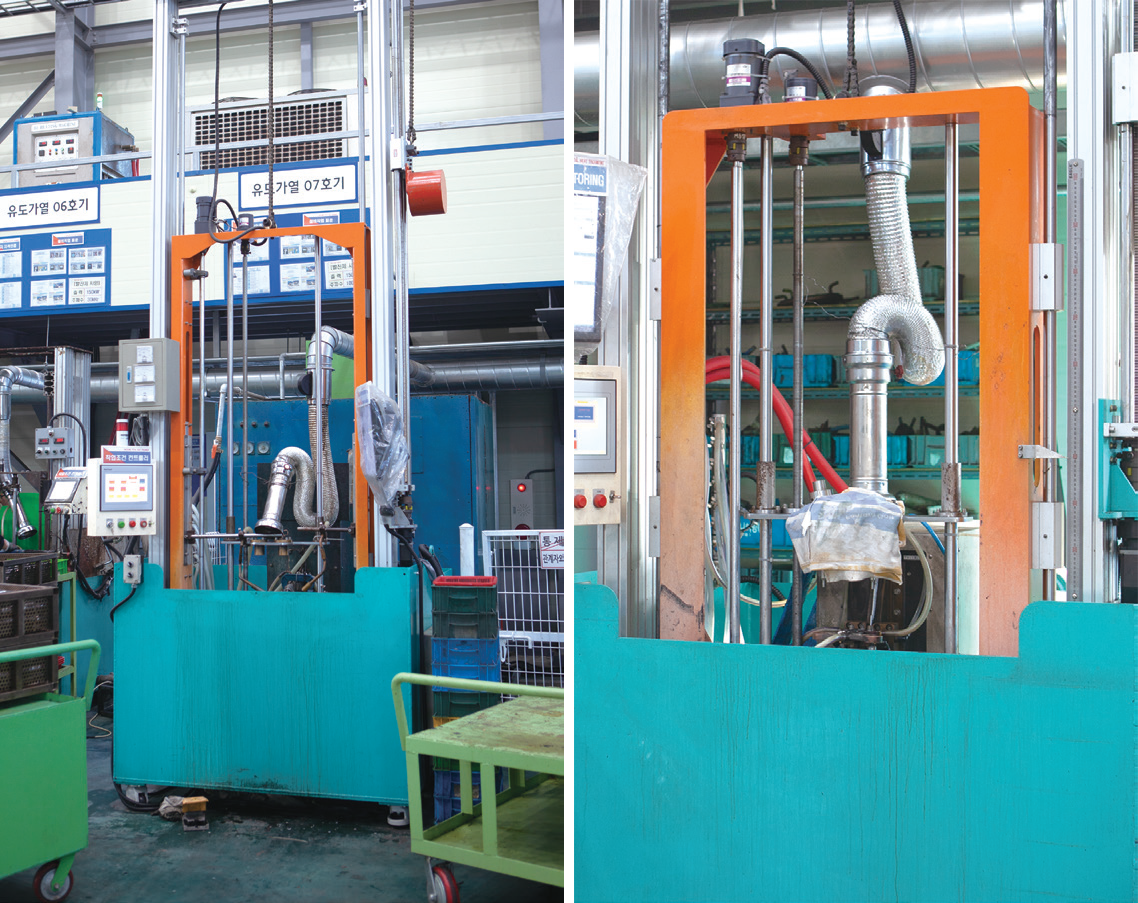

As an equipment to perform the high frequency heat treatment with the descent transfer through the rotation after fixing the product using vertical center and can perform high frequency heat treatment for the product having total length of 3,000 mm.

As an equipment to perform the high frequency heat treatment with the descent transfer through the rotation after fixing the product using vertical center and can perform high frequency heat treatment for the product having total length of 1,000 mm.

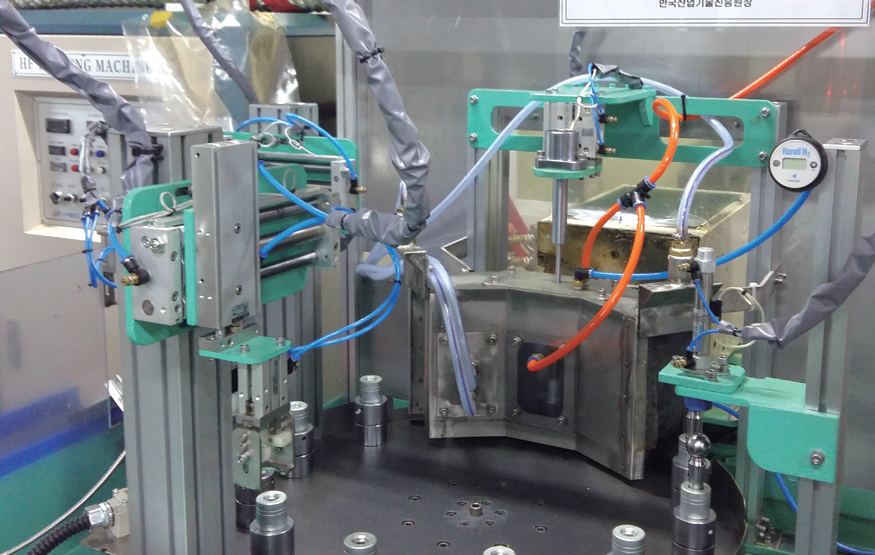

As an equipment to perform the heat treatment with 4 stages of product feeding, heating, cooling and discharge as one continuous process within turntable rotary jig and has a production capacity more than 3 times and excellent quality than the existing manual work.

New concept of automated high frequency heat treatment equipment grafted with the technology to inhibiting oxide scale on the surface by performing the induction heating within the non-oxidizing ambient.

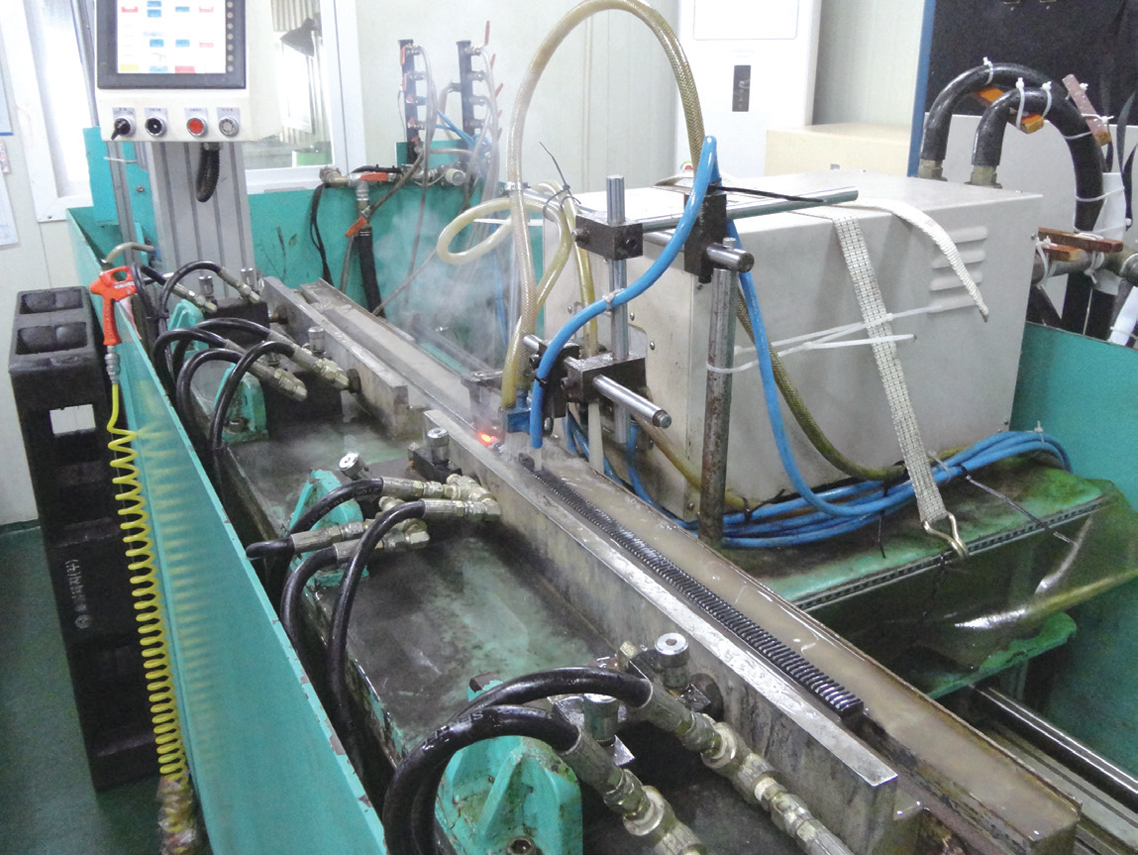

The high frequency heat treatment has been performed typically using the descent transfer with vertical center or static heating, but the relevant equipment is the automated equipment that enables the continuous process with the product feeding through horizontal transfer of the product.

The high frequency heat treatment is typically performed by moving heated object while the CT-Box equipped with high frequency coil is fixed but the relevant equipment is the automated equipment that the high frequency heat treatment is performed by moving CT-box equipped with high frequency coil.

Since the high frequency heat treatment applies the rapid heating and rapid cooling on the product, the stress remains in the hardened area of the product, which represents that the brittleness is high. Since the brittleness is the cause of relevant product's fracture, the fracture by the brittleness is prevented by granting the toughness through application of tempering. The relevant heating furnace is the facility to perform the tempering process.